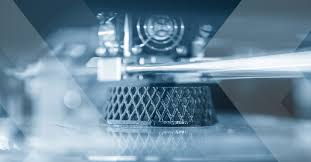

3D printing, also known as additive manufacturing, is a revolutionary process in which three-dimensional objects are created by layering material based on digital models. This technology, once primarily used for prototyping, has expanded into various industries, from healthcare to aerospace, due to its ability to create complex geometries and customized designs.

Unlike traditional manufacturing methods like injection molding or CNC machining, which subtract material from a larger block, 3D printing builds objects layer by layer, offering greater precision and efficiency. In this article, we will explore the diverse applications of 3D printing and its future trends.

Applications of 3D Printing

1. Healthcare and Medicine

3D printing has made significant strides in healthcare, enabling groundbreaking innovations in both research and clinical applications. The technology’s ability to create customized prosthetics, implants, and even organs is transforming the medical field.

Customized Prosthetics and Implants: Traditional prosthetics are often mass-produced, meaning they may not fit well or meet the specific needs of the individual. 3D printing allows for the design and production of bespoke prosthetics tailored to an individual’s body shape. This is not only cost-effective but also provides a higher level of comfort and functionality for the patient.

Bioprinting: Perhaps the most exciting development in 3D printing within healthcare is bioprinting, which involves the use of living cells to create tissue and, potentially, organs. Although this technology is still in the early stages, researchers are optimistic that 3D printing will one day allow for the production of functional organs for transplants, significantly reducing the current shortage.

Medical Models for Surgical Planning: Surgeons can use 3D-printed models of a patient’s anatomy to plan complex surgeries. These models, often based on medical imaging data (CT or MRI scans), allow doctors to practice and refine their techniques before performing the procedure. This not only improves outcomes but also reduces the risk of complications.

2. Aerospace and Aviation

The aerospace industry has embraced 3D printing for both the manufacturing of parts and the rapid prototyping of new designs. The ability to produce lightweight, complex geometries is critical in an industry where reducing weight can lead to significant fuel savings and efficiency gains.

Lightweight Components: One of the primary benefits of 3D printing in aerospace is the ability to create lightweight yet strong components. Traditional manufacturing methods often require materials to be bulkier or less optimized, but 3D printing allows engineers to design parts that are both lighter and more durable.

On-Demand Spare Parts: Airlines can use 3D printing to produce spare parts on demand, reducing the need to keep large inventories of expensive, hard-to-find parts. This can significantly reduce operational costs and lead times, as well as minimize aircraft downtime.

Rapid Prototyping and Testing: Aerospace companies use 3D printing for prototyping new components and testing them in real-world conditions. This process enables companies to experiment with new designs quickly and economically, ensuring that only the best innovations make it to production.

3. Automotive Industry

The automotive industry has also found substantial use for 3D printing in manufacturing and design, enhancing both the production process and the performance of vehicles.

Prototyping and Design Iteration: Automotive manufacturers use 3D printing to prototype parts and systems, allowing for rapid iterations and changes to designs before committing to mass production. This helps reduce costs and accelerate the development cycle.

End-Use Parts: In some cases, 3D printing is used to manufacture functional, end-use parts for vehicles. For instance, 3D-printed car parts such as interior components, engine components, and even custom wheels have been produced. These parts can be made lighter, more durable, and more cost-effective.

Customization: Another key application in the automotive sector is customization. Car owners can use 3D printing to create personalized interior features or even external body modifications. This level of customization allows automotive brands to cater to niche markets and offer a more personalized experience for customers.

4. Construction and Architecture

3D printing is beginning to play an essential role in the construction industry, from printing individual building components to whole structures.

Printing Buildings and Structures: The most exciting application of 3D printing in construction is the ability to print entire buildings or homes. 3D-printed concrete allows for the creation of homes and infrastructure with minimal labor, reducing both the cost and time needed to construct buildings. Some companies are already developing entire 3D-printed homes, especially in regions where traditional construction materials are scarce.

Customizable Designs: 3D printing enables architects and engineers to experiment with unique designs and geometries that would be difficult or impossible to achieve using conventional construction methods. This can lead to more sustainable, efficient, and aesthetically pleasing structures.

Construction of Infrastructure: In addition to homes, 3D printing can also be used for creating bridges, roads, and other infrastructure elements. The precise nature of 3D printing ensures that these structures are not only durable but also designed with optimization in mind.

5. Consumer Goods and Fashion

3D printing in consumer goods and fashion has made it possible to create bespoke products and accessories tailored to individual preferences.

Custom Jewelry: Jewelry designers are using 3D printing to create intricate and customized pieces. Because the printing process is highly precise, it allows for the creation of unique designs that would be difficult to achieve using traditional methods.

Fashion and Wearables: Fashion designers are experimenting with 3D-printed clothing and accessories. The flexibility and customization capabilities of 3D printing allow for the creation of intricate designs and personalized items. For example, 3D-printed shoes and dresses have appeared on runways, marking a fusion of technology and fashion.

Personalized Products: Beyond jewelry and fashion, 3D printing enables the mass customization of everyday consumer goods, such as eyewear, footwear, and home decor. Companies can now produce items that perfectly match the tastes, sizes, and needs of individual consumers.

READ ALSO: How Technology is Revolutionizing the Healthcare Industry

Future Trends in 3D Printing

As 3D printing technology continues to evolve, we can expect to see several trends emerge in the coming years. These trends will shape the future of industries ranging from healthcare to manufacturing and even art.

1. Materials Innovation

One of the biggest advancements in 3D printing will come from the development of new materials. These new materials will open up new possibilities for industries like construction, healthcare, and aerospace.

2. Large-Scale 3D Printing

As technology advances, 3D printers are becoming larger, enabling the printing of large-scale objects. This could revolutionize industries such as construction, where 3D printers might one day be used to print entire buildings or infrastructure.

3. Increased Speed and Efficiency

Currently, 3D printing can be a slow process, particularly for large or intricate objects. However, with new developments in print speed, efficiency, and automation, 3D printing is expected to become much faster, making it more competitive with traditional manufacturing methods in terms of time and cost.

4. AI and Machine Learning Integration

These technologies will help optimize designs, predict failures, and improve the overall quality of the printed products. AI could also enable more advanced automation, reducing the need for human intervention in the printing process.

5. Sustainability and Eco-friendly Solutions

Sustainability is another key trend driving the future of 3D printing. As the technology advances, there will likely be more emphasis on recycling and reusing materials.

FAQs

What materials can be used in 3D printing?

3D printing can use a variety of materials, including plastics (such as PLA and ABS), metals (like titanium and stainless steel), ceramics, and composites.

Is 3D printing environmentally friendly?

While 3D printing can be more sustainable than traditional manufacturing because it produces less waste, it still has environmental concerns, especially regarding the use of plastic materials. However, research is ongoing to develop more eco-friendly materials and processes.

What are the limitations of 3D printing?

Despite its many benefits, 3D printing has some limitations, such as slower production speeds for large-scale objects, material limitations, and high initial costs for industrial-grade printers.

Will 3D printing replace traditional manufacturing?

While 3D printing is a revolutionary technology, it is unlikely to replace traditional manufacturing entirely. However, it will complement conventional methods, particularly in industries that require rapid prototyping,